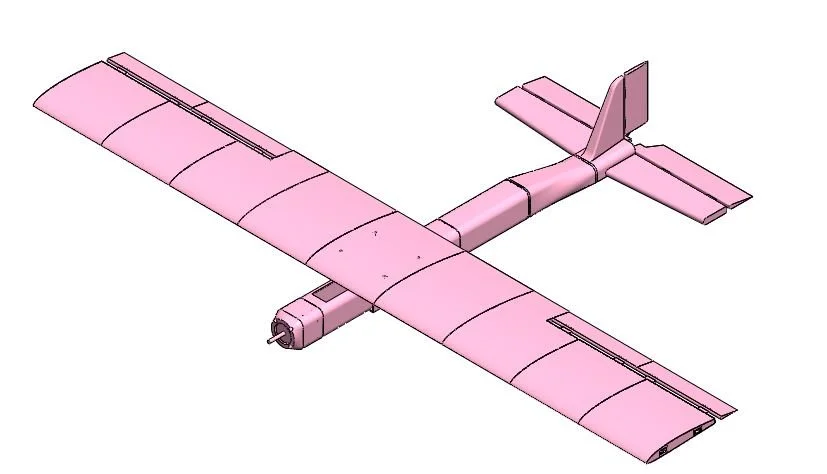

This project details the design, development, and fabrication of a 3D-printed fixed-wing aircraft created for the CSU LA 3D Printed Aircraft Competition. The objective was to engineer a lightweight, structurally sound, and aerodynamically efficient aircraft using additive manufacturing techniques. The design process included extensive research, iterative CAD modeling, prototyping, and hands-on assembly. Multiple versions of the fuselage and wing configurations were developed and tested to optimize performance and structural integrity. Rapid iteration through 3D printing enabled efficient testing and refinement cycles. The final aircraft design earned 1st place in the competition’s design category and 2nd place in flight duration.

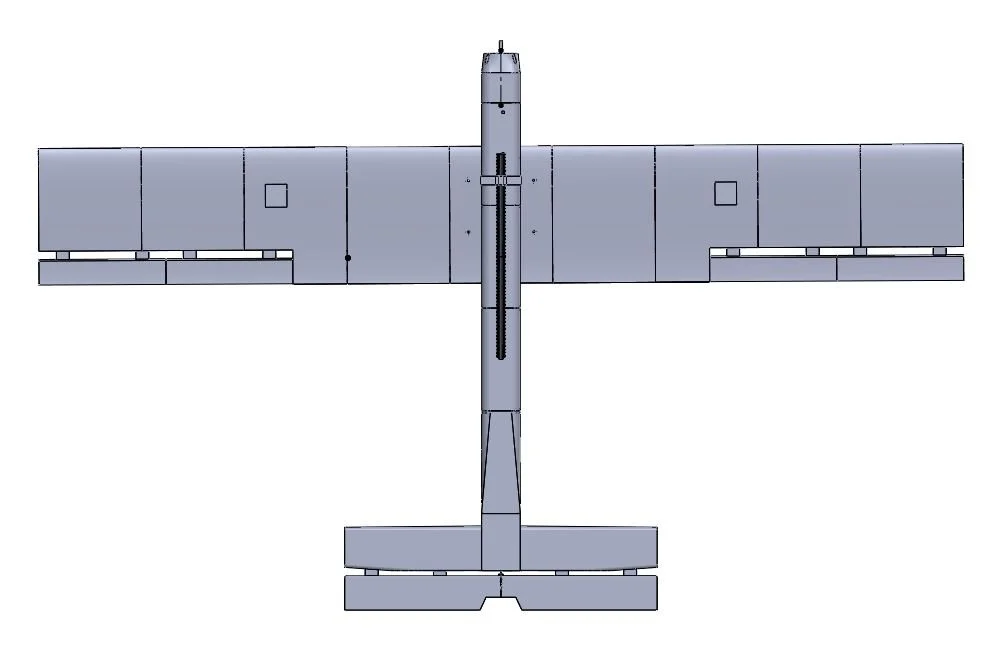

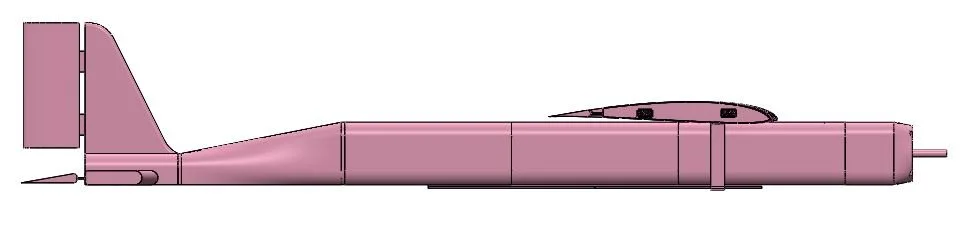

System Level Diagram

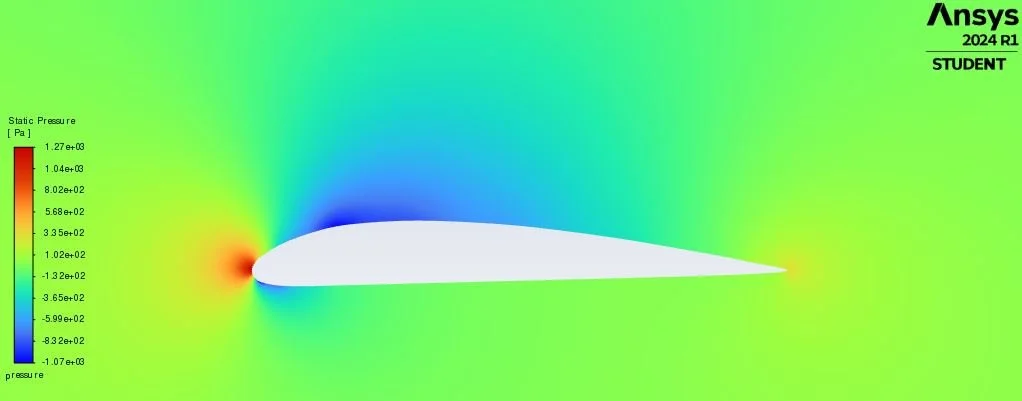

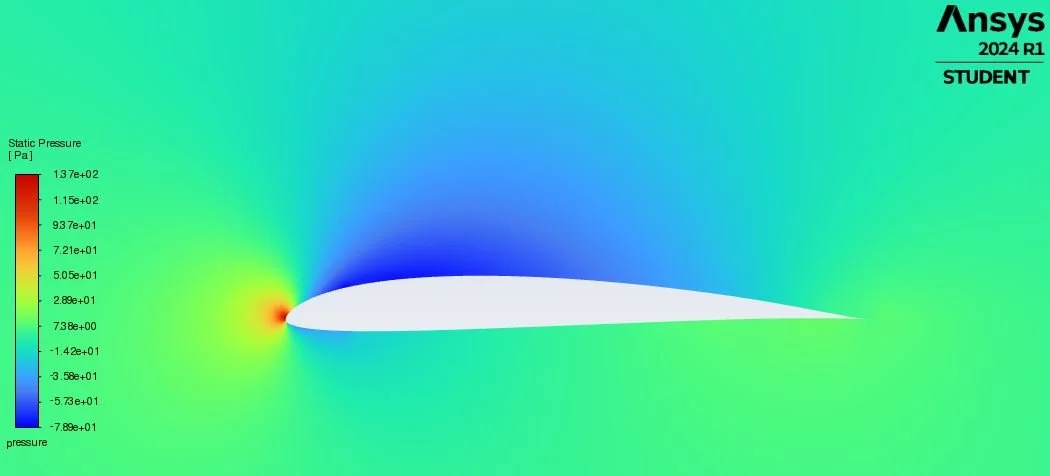

Finite Element Analysis of SD7037 and Geo285 airfoils

SD7037 Airfoil

Geo285 Airfoil

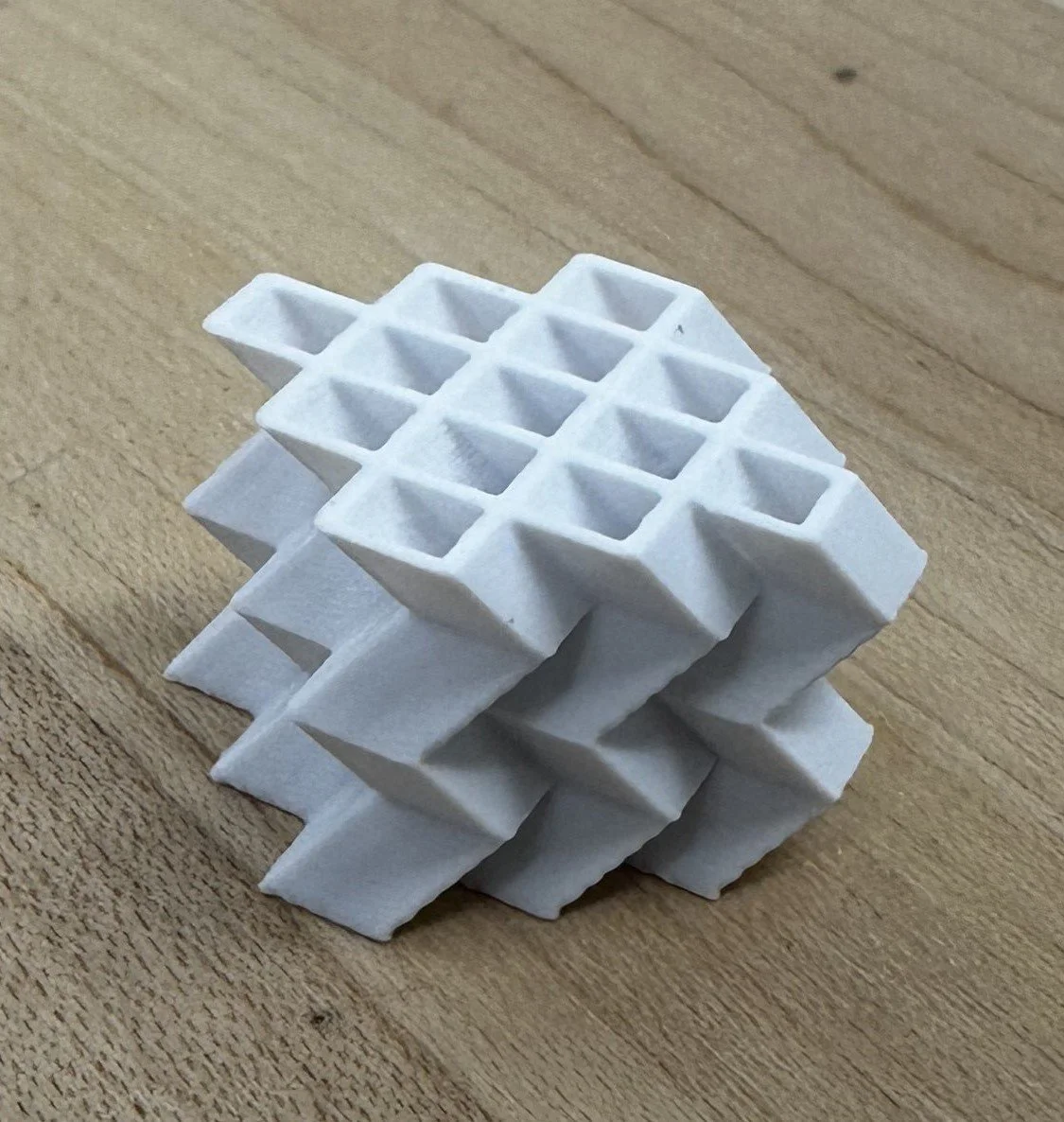

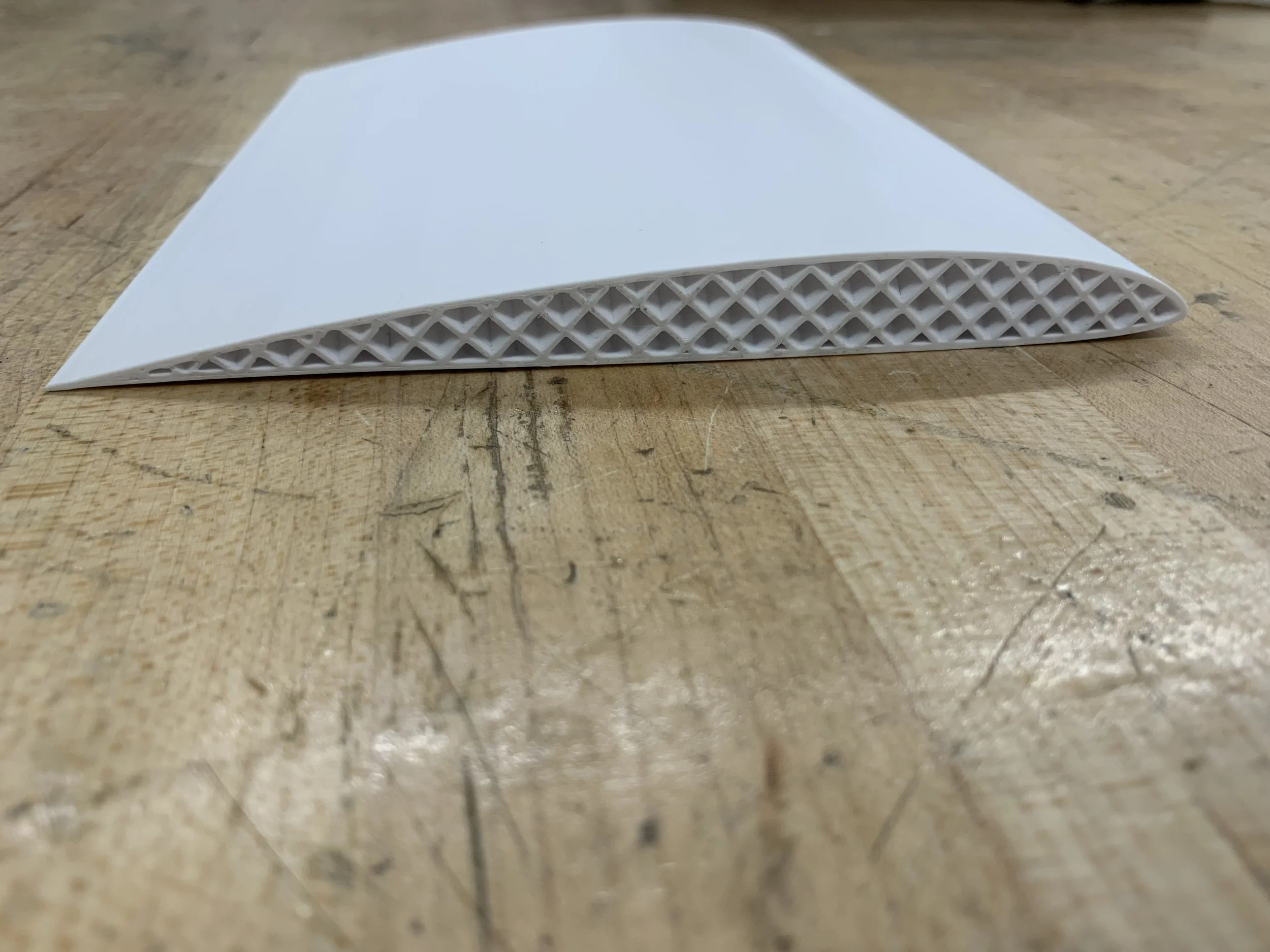

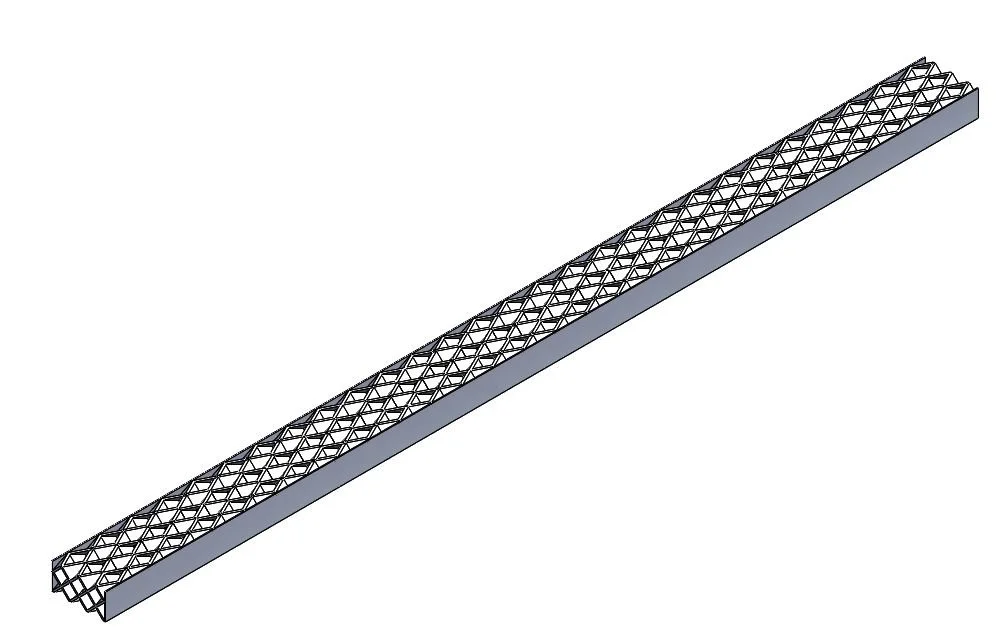

Implementation of Origami Structure

Origami Structure

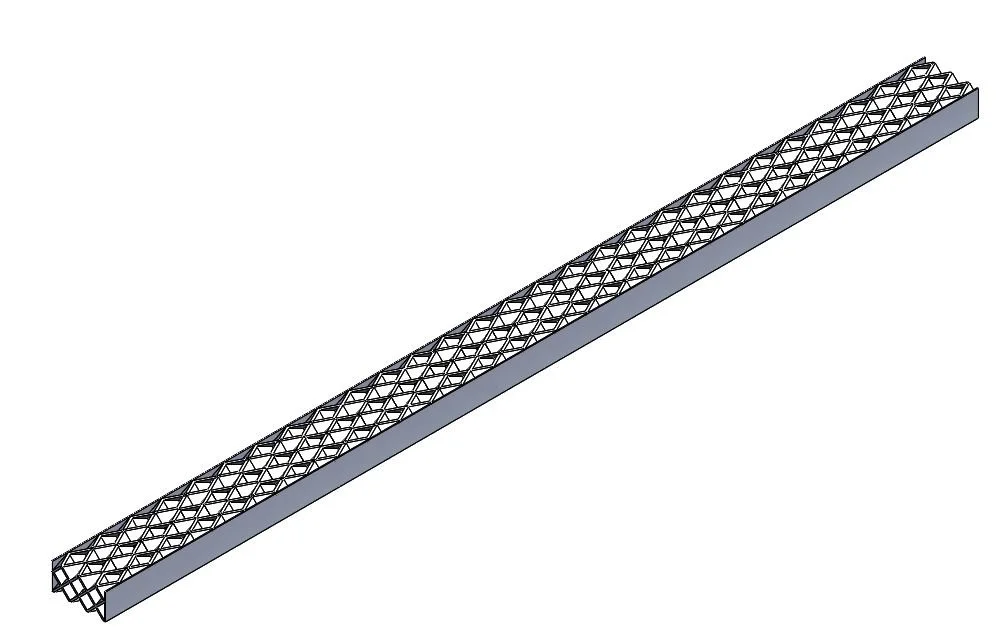

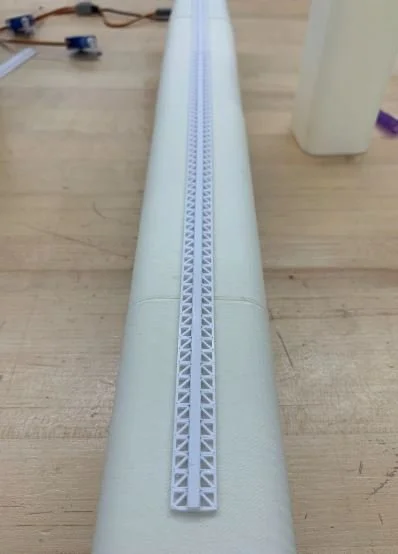

Spar Skeleton

Spar Exterior

8in. spar section holding 20lbs

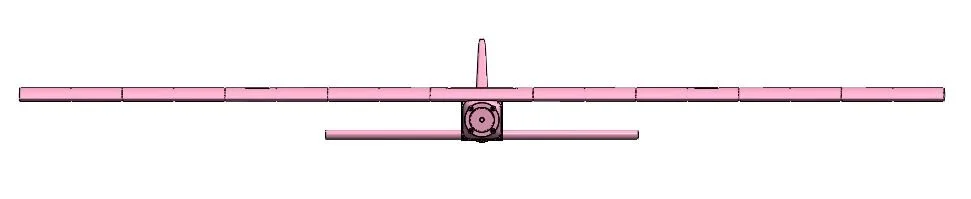

Wing Iterations

Origami structure printed in the wing section.

Transitioned to having spars printed with origami structure resulting in this wing iteration.

Final iteration printed with walls on both ends to allow for easy assembly.

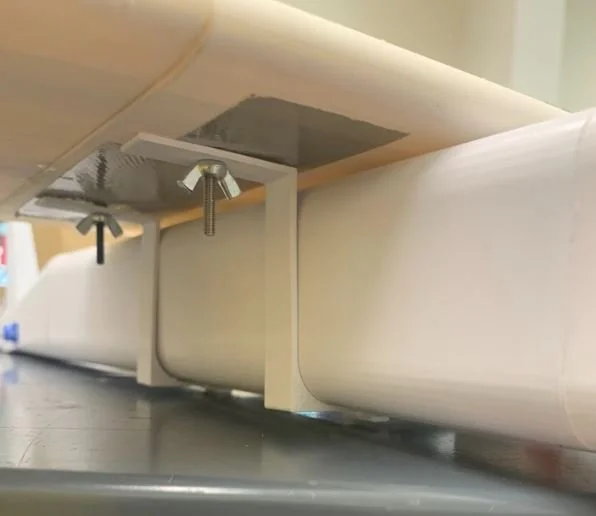

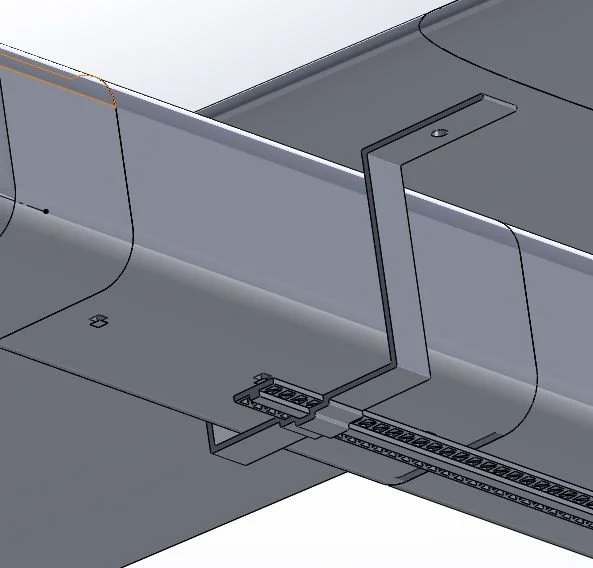

Rail System

A U-bracket rail system was designed to allow for the wing to slide along the fuselage in order to locate the center of gravity along with being able to change out parts if needed.

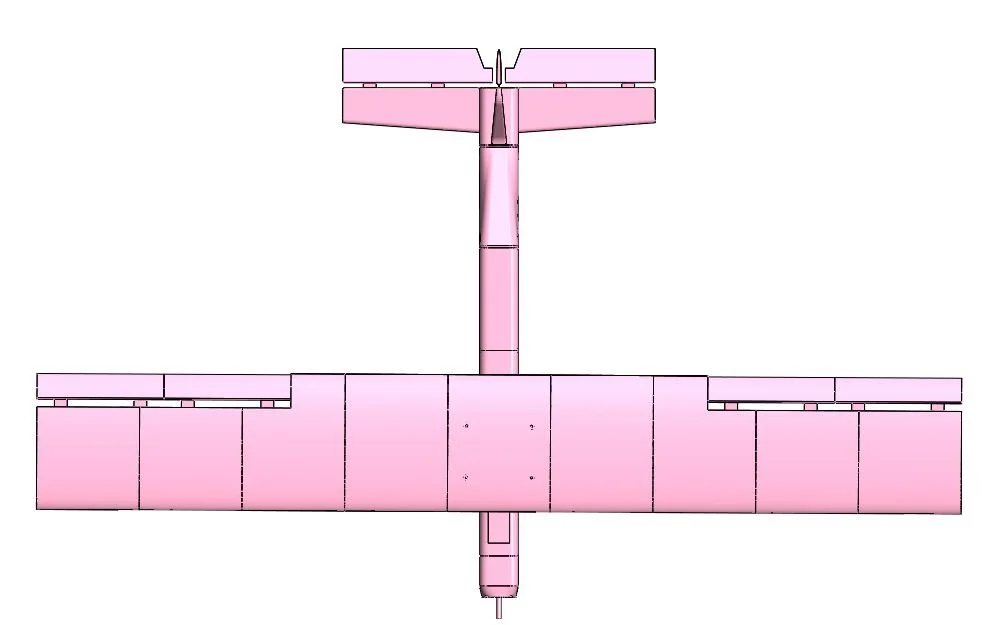

TPU Hinges

In order to attach the rudder, elevator and ailerons, TPU hinges were 3D printed. Allowing for the respective part to have full range of motion.

Rudder

Elevator

Aileron

Fully Constructed Plane

First successful flight

Flight that took 2nd place in flight duration